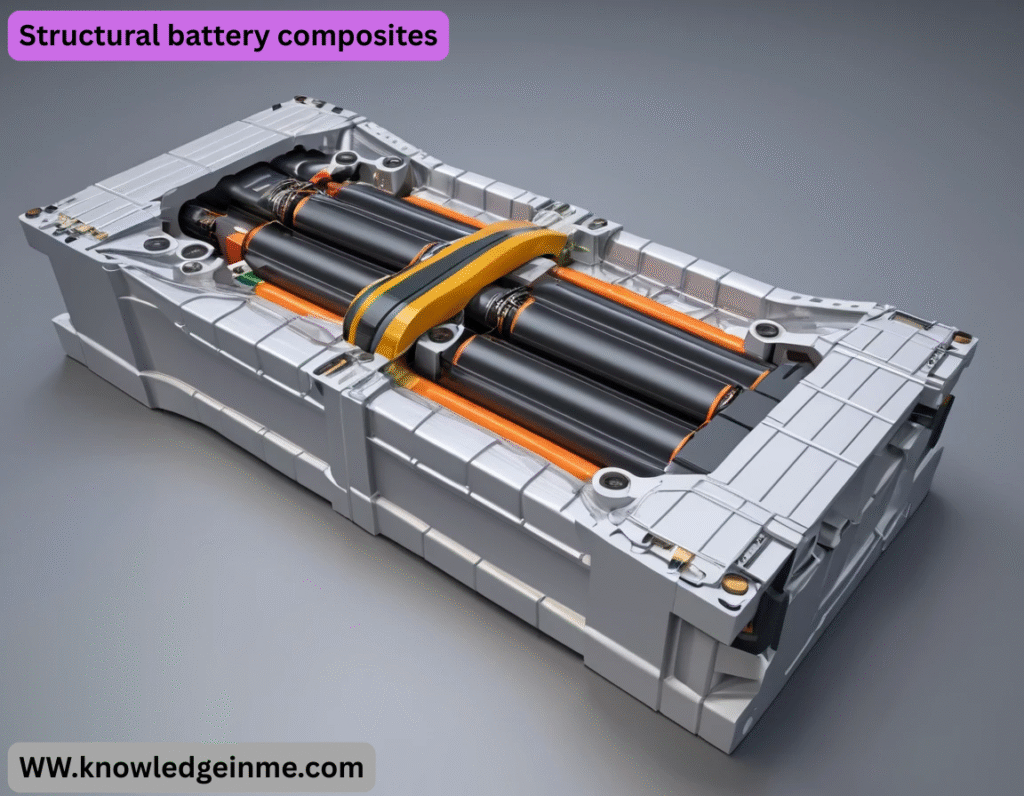

Structural battery composites (SBCs) represent a cutting-edge innovation in materials science, combining load-bearing capability with energy storage in a single multifunctional material. By integrating the functions of a battery and a structural component, SBCs aim to reduce weight, improve efficiency, and enable new design possibilities in applications like electric vehicles (EVs), aerospace, and portable electronics.

Concept & Working Principle

- Traditional batteries (e.g., Li-ion) are add-on components that occupy space and add weight without contributing to structural integrity. In contrast, SBCs merge the electrode and electrolyte materials into a composite structure, allowing them to:

- Store energy (like a battery).

- Withstand mechanical loads (like a structural material).

Key Components:

- Structural Electrodes: Carbon fibers (anode) and lithium-coated fibers (cathode) serve dual roles (conductivity + strength).

- Solid Polymer Electrolyte: Replaces liquid electrolyte, providing ionic conductivity while maintaining mechanical stability.

- Reinforcement Matrix: Often epoxy or other polymers that bind fibers while allowing ion transport.

Advantages of Structural Batteries

- Weight Reduction: Eliminates separate battery packs, crucial for EVs and aircraft.

- Space Efficiency: More compact designs possible.

- Improved Energy Density: Multifunctionality enhances system-level efficiency.

- Enhanced Safety: Solid electrolytes reduce leakage/thermal risks.

Challenges & Limitations

- Trade-off Between Strength & Energy Storage: Optimizing one property may compromise the other.

- Cycle Life & Durability: Repeated mechanical stress may degrade performance.

- Cost: Advanced materials (e.g., carbon fiber, solid electrolytes) are expensive.

Current Research & Developments

- Solid-State Electrolytes: Safer and more mechanically robust than liquid electrolytes.

- 3D-Printed SBCs: Additive manufacturing enables customized designs.

- Self-Healing Composites: To extend lifespan under mechanical stress.

Potential Applications

- Electric Vehicles: Lighter cars with longer range.

- Aerospace: Reduced weight in drones, satellites, and aircraft.

- Wearable Electronics: Flexible, load-bearing energy storage.

- Civil Engineering: Smart infrastructure with energy-storing components.

Core Materials & Design Approaches

Electrode Materials

- SBCs require electrodes that are both structurally robust and electrochemically active.

Anode Materials

- Carbon Fiber (CF) Anodes:

- High stiffness (~200–500 GPA) and conductivity.

- Can intercalate lithium ions (Li⁺) for energy storage.

Silicon-Carbon Hybrids:

- Research focuses on nanostructured Si to mitigate cracking.

Cathode Materials

- Lithium Iron Phosphate (LFP)-Coated Fibers:

- Good stability but lower energy density.

- Lithium Nickel Manganese Cobalt Oxide (NMC) Composites:

- Higher energy density but more sensitive to mechanical stress.

Structural Conductive Polymers:

- Polymeric cathodes (e.g., polyaniline) with embedded active materials.

Electrolyte Systems

- Since liquid electrolytes compromise mechanical properties, solid-state electrolytes (SSEs) are preferred:

- Polymer Electrolytes (e.g., PEO-LiTFSI):

- Ceramic Electrolytes (e.g., LLZO, Li₇La₃Zr₂O₁₂):

- High modulus (~150 GPA) but brittle.

Hybrid Solid Electrolytes:

- Combining polymers with ceramics (e.g., PEO + LLZO nanoparticles) for balanced properties.

Matrix Materials

The matrix binds fibers while allowing ion transport

- Structural Polymers (Epoxy, PMMA):

- High strength but poor ionic conductivity.

Ion-Conducting Polymers:

- Modified epoxies with Li⁺ pathways (e.g., epoxy-LIClO₄).

State of the Art Research 2020 2024

- Chalmers University (Sweden) – Carbon Fiber SBCs

Performance:

- Energy density: 24 WH/kg (structural) vs. ~250 WH/kg (Li-ion).

- Stiffness: ~25 GPA (vs. ~70 GPA for CF/epoxy).

- Limitation: Low energy density due to thick electrolyte layers.

University of Michigan – Solid-State SBCs

- Design: Glass-fiber-reinforced SSE with Li-metal anode.

Performance:

- Flexural strength: ~300 MPA.

- Capacity retention: 80% after 100 cycles.

NASA – SBCs for Aerospace

- Goal: Replace satellite structural panels with energy-storing composites.

- Approach: 3D-printed graphene-lithium cells embedded in epoxy.

Key Challenges & Future Directions

Major Challenges

- Low Energy Density: Current SBCs store <25% energy of Li-ion.

- Cycle Life Degradation: Mechanical stress accelerates capacity fade.

- Manufacturing Scalability: Hand layup vs. automated fiber placement (AFP).

- Cost: High-performance carbon fiber + solid electrolytes are expensive.

Emerging Solutions

- Self-Healing Electrolytes: Polymers that repair cracks.

- Multiscale Modeling: AI-driven optimization of microstructures.

- Hybrid Energy Systems: Combining SBCs with supercapacitors for burst power.

Advanced Fabrication Techniques for SBCs

Fiber-Based Manufacturing

- Continuous Fiber Electrodes

- Process: Carbon fibers are coated with active materials (e.g., Si for anodes, LFP for cathodes) via:

- Electrophoretic Deposition (EPD)

- Chemical Vapor Deposition (CVD)

- Example: Chalmers University’s roll-to-roll coated CF anodes.

Multifunctional Weaving

- Approach: Interlacing conductive fibers (anode/cathode) with insulating separators.

- Challenge: Preventing short circuits while ensuring ion transport.

Solid Electrolyte Integration

- In-Situ Polymerization

- Liquid monomer infused into fiber layers, then cured (e.g., UV-polymerized PEGDA).

- Advantage: Ensures intimate electrode-electrolyte contact.

- Ceramic-Polymer Hybrid Electrolytes

- Example: LLZO (Li₇La₃Zr₂O₁₂) nanoparticles dispersed in PEO matrix.

- Benefit: Combines high ionic conductivity (10⁻⁴ S/cm) with mechanical robustness.

Additive Manufacturing (3D Printing)

- Direct Ink Writing (DIW)

- Materials: Shear-thinning inks with carbon fibers + Li-active materials.

- Application: Customized battery shapes (e.g., drone wings).

Selective Laser Sintering (SLS)

- Process: Laser-fuses polymer/ceramic powders into solid electrolytes.

- Example: NASA’s 3D-printed graphene-LiMn₂O₄ cells.

Industry Prototypes & Case Studies

Electric Vehicles (EVs)

- Volvo’s SBC Car Project (2021–Present)

Performance:

- 50% weight reduction vs. steel + battery pack.

- Energy contribution: ~1 kWh (supplementary to main battery).

- Tesla’s Structural Battery Patents (2023)

- Concept: Aluminum honeycomb cells with Li-ion electrodes.

- Goal: Replace floor panels in Cyber truck.

Aerospace & Defense

- Airbus’ “Wing of Tomorrow” (2025 Target)

- SBC Role: Energy-storing wing spars for hybrid-electric aircraft.

- Challenge: Achieving FAA-certifiable mechanical stability.

Lockheed Martin’s Satellite Panels

- Approach: Si-anode SBCs replacing aluminum chassis in CubeSats.

- Benefit: 30% mass savings → lower launch costs.

Consumer Electronics

- Samsung’s Foldable Phone Battery (Patent)

- Design: Carbon-nanotube-reinforced Li-polymer cells.

- Advantage: Bendable yet rigid enough for hinge support.

Roadmap: From Lab to Market

Short-Term (2024–2028)

- Focus: Improve cycle life (>500 cycles) and energy density (>50 WH/kg).

Applications:

- High-end drones (e.g., military UAVs).

- Luxury EV components (e.g., door panels).

- Medium-Term (2028–2035)

Goals:

- Energy density >100 WH/kg (competitive with conventional Li-ion).

- Automated mass production (e.g., AFP for automotive).

Applications:

Mainstream EV structural packs (replacing 20–30% of body-in-white).

- EVTOL aircraft primary structures.

- Long-Term (Post-2035)

Vision:

- “Battery-less” EVs: Entire chassis as energy storage.

- Self-powered infrastructure: Bridges with SBCs storing solar energy.

Breakthroughs Needed:

- AI-optimized materials: Machine learning for composite design.

- Room-temperature solid-state SBCs: Eliminating thermal management.

Open Questions & Debates

- “Is energy density or mechanical performance the limiting factor?”

- Argument: For EVs, energy density is critical; for aerospace, strength matters more.

“Can SBCs ever fully replace Li-ion packs?”

- Counterpoint: Likely hybrid systems (SBCs + conventional batteries) will dominate.

Failure Mechanisms & Durability Challenges

Critical Failure Modes

- Electrochemical-Mechanical Decoupling

- Problem: Repeated charge/discharge causes swelling/contraction → fiber-matrix debonding

- Example: Silicon anodes expand ~300% → composite delamination in <50 cycles

- Dendrite Penetration in Solid Electrolytes

Current Solutions:

- Nanostructured ceramic electrolytes (LLZO with Al doping)

- Polymer-ceramic “sandwich” layers (UMICH 2023 design)

Interfacial Degradation

- Data: 40% impedance increase after 100 cycles (Chalmers 2022 study)

- Innovation: Atomic layer deposition (ALD) of Al₂O₃ on fibers

TCO Comparison (EV Battery Pack)

- Conventional: $140/kWh + $12/kg structural weight

- SBC (2030): $210/kWh (but eliminates $8/kg structural cost)

- Break-even Point: 400km+ range vehicles (Volvo 2025 analysis)