Digital Twins Below is an expanded breakdown covering how they work, industry-specific applications, underlying technologies, challenges, and future advancements.

Key Components of Digital Twins

- Physical Entity – The real-world object (e.g., a machine, building, or supply chain).

- Virtual Model – A digital replica created using 3D modeling, simulations, or AI.

- Data Connectivity – Sensors and IoT devices feed real-time data into the virtual model.

- Analytics & AI – Processes data to provide insights, predict failures, and optimize performance.

- User Interface (UI) – Allows interaction with the digital twin (e.g., dashboards, AR/VR).

Types of Digital Twins

- Product Twins – Simulate individual products (e.g., a jet engine).

- Process Twins – Optimize manufacturing or business workflows.

- System Twins – Model complex systems (e.g., smart cities, power grids).

Applications of Digital Twins

- Manufacturing – Predictive maintenance, quality control.

- Healthcare – Personalized medicine, virtual patient models.

- Smart Cities – Traffic management, infrastructure monitoring.

- Aerospace – Aircraft performance tracking.

- Energy – Wind turbine optimization, grid management.

Benefits

- Predictive Maintenance – Reduces downtime by anticipating failures.

- Cost Savings – Optimizes operations and resource use.

- Improved Innovation – Faster prototyping and testing.

- Enhanced Decision-Making – Real-time insights for better strategies.

Challenges

- Data Security & Privacy – Risk of cyber threats.

- High Initial Costs – Requires IoT infrastructure & advanced analytics.

- Integration Complexity – Needs seamless connectivity between systems.

Future Trends

- AI & Machine Learning – Smarter, self-learning digital twins.

- Metaverse Integration – Virtual collaboration using AR/VR.

- 5G & Edge Computing – Faster, real-time data processing.

How Digital Twins Work

- Data Collection – Sensors, IoT devices, and edge computing gather real-time data (e.g., temperature, vibration, pressure).

- Data Transmission – Cloud or edge networks process and transmit data to the digital model.

- Virtual Modeling – A 3D or mathematical model mimics the physical asset’s behavior.

- AI & Analytics – Machine learning algorithms analyze data to predict failures, optimize performance, and simulate scenarios.

- Actionable Insights – The system recommends adjustments (e.g., maintenance alerts, efficiency improvements).

Example:

- A wind turbine’s digital twin collects vibration data → AI predicts bearing failure → Maintenance is scheduled before breakdown.

Industry Specific Use Cases

Manufacturing & Industry 4.0

- Predictive Maintenance – Detects machine wear before failure.

- Production Optimization – Simulates assembly line changes to improve efficiency.

- Quality Control – Uses AI to detect defects in real time.

Smart Cities & Infrastructure

- Traffic Management – Adjusts signals in real time based on congestion data.

- Structural Health Monitoring – Tracks bridges/buildings for stress and wear.

- Example: Singapore’s Virtual Singapore is a city-wide digital twin for urban planning.

Aerospace & Defense

- Aircraft Health Monitoring – Tracks engine performance mid-flight.

- Flight Simulation – Tests new designs virtually before production.

- Space Exploration – NASA uses digital twins for Mars rovers.

- Example: GE Aviation monitors jet engines in real time to prevent failures.

Healthcare & Medicine

- Patient-Specific Models – Simulates drug effects on virtual organs.

- Surgical Planning – Surgeons practice complex operations on digital replicas.

- Medical Device Testing – Validates implants before real-world use.

- Example: The Living Heart Project by Dassault Systèmes simulates human heart behavior.

Energy & Utilities

- Smart Grids – Predicts electricity demand and adjusts supply.

- Oil & Gas Pipelines – Detects leaks or corrosion early.

- Renewable Energy – Optimizes wind/solar farm layouts.

- Example: BP uses digital twins to monitor offshore rigs, improving safety.

The Future of Digital Twins

Emerging Trends

- AI-Powered Self-Learning Twins – Automatically adapt to changes without human input.

- Metaverse Integration – Digital twins merge with VR/AR for immersive collaboration.

- Quantum Computing – Enables ultra-complex simulations (e.g., climate modeling).

- Autonomous Systems – Self-healing infrastructure (e.g., smart grids that auto-repair).

The Evolution of Digital Twins: A Historical Perspective

Digital twins aren’t a new concept—NASA pioneered early versions in the 1960s for spacecraft simulations. However, the convergence of IoT, AI, and cloud computing has supercharged their capabilities:

- 1960s-2000s: Basic simulation models (e.g., Apollo mission simulations)

- 2010s: IoT-enabled real-time monitoring (Industry 4.0)

- 2020s: AI-powered predictive twins with autonomous decision-making

- Future: Quantum digital twins for ultra-complex systems (e.g., climate modeling)

Advanced Technical Architecture of Digital Twins

Modern digital twins use a multi-layered stack:

- Physical Layer: Sensors (vibration, thermal, pressure), actuators, RFID tags

- Data Layer: Edge computing for preprocessing + cloud storage (AWS IoT, Azure Digital Twins)

Modeling Layer:

- Physics-based models (FEA, CFD)

- Data-driven models (LSTM neural networks, reinforcement learning)

Integration Layer:

- APIs for ERP/MES systems (SAP, Siemens Teamcenter)

- Digital Thread for lifecycle management

Visualization Layer:

- Unity/Unreal Engine for 3D rendering

- AR/VR interfaces (Microsoft HoloLens, NVIDIA Omni verse)

- Example: A Formula 1 car’s digital twin processes 300+ sensors at 10,000 Hz, with AI predicting tire wear during races.

Next-Gen Industry Applications

Energy Sector Breakthroughs

- Nuclear Fusion: Tokamak reactors use digital twins to simulate plasma behavior (ITER project)

- Hydrogen Economy: Electrolyzer twins optimize green hydrogen production efficiency

Autonomous Vehicle Development

- Sensor Fusion Testing: Simulating lidar/camera data for edge cases (Waymo’s Car craft)

- Battery Degradation Modeling: Predicting EV battery lifespan under different conditions

Biotechnology Innovations

- Organ-on-a-Chip: Human organ twins for drug testing (Emulate Inc.)

- Genomic Digital Twins: Personalized cancer treatment simulations

Space Industry Applications

- Satellite Constellation Management: Predicting orbital collisions (SpaceX Star link)

- Lunar Base Simulations: Testing habitat designs for Artemis missions

Cutting Edge Research Frontiers

Distributed Digital Twins

- Blockchain-secured twins across supply chains (Maersk+IBM Trade Lens)

- Federated learning for privacy-preserving hospital twins

Neuromorphic Digital Twins

- Brain-inspired chips (Intel Loihi) enabling real-time physics simulation

- Spiking neural networks for ultra-low-power edge twins

Quantum Digital Twins

- D-Wave quantum annealing for material science simulations

- QUBO models optimizing city-scale traffic flows

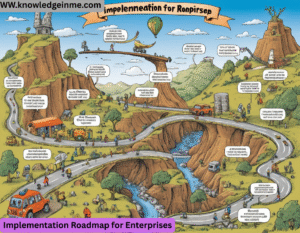

Implementation Roadmap for Enterprises

- Phase 1: Foundation (6-12 months)

- Deploy IoT sensors + edge gateways

- Build basic dashboard visualizations

- Phase 2: Enhancement (1-2 years)

- Integrate ML for anomaly detection

- Develop physics-based simulation models

- Phase 3: Transformation (3-5 years)

- Implement autonomous control loops

- Establish digital thread across product lifecycle

- Pro Tip: Start with high-value assets (e.g., critical manufacturing equipment) before scaling.

Financial Impact Analysis

- ROI Case Study: Shell’s offshore platform twins reduced inspection costs by $2M/year per rig

Cost Breakdown:

- Sensors/Connectivity: 15-25%

- Cloud/AI Infrastructure: 30-40%

- Change Management: 35-50%

Ethical and Regulatory Challenges

- Deep fake Twins: Potential for malicious simulation of people/equipment

- IP Protection: Who owns the twin’s AI-generated insights?

- EU AI Act Compliance: High-risk twins requiring certification

Future Vision 2030 and Beyond

- Planetary-Scale Twins: Climate change modeling with billion-node simulations

- Conscious Digital Twins: Ethical debates on sentient AI replicas

- Bio-Digital Convergence: Human twins that age with you for personalized medic

IX. The Dark Side of Digital Twins

- Simulation Addiction: Over-reliance on digital vs. physical

- Reality Hacking: Malicious manipulation of twin data

- Existential Risks: When twins become more “real” than reality

X. Implementation Checklist

Pre-Deployment

- Asset criticality assessment

- Data governance framework

- ROI calculation model

- Deployment

- Sensor calibration protocol

- Model validation suite

- Failover mechanisms