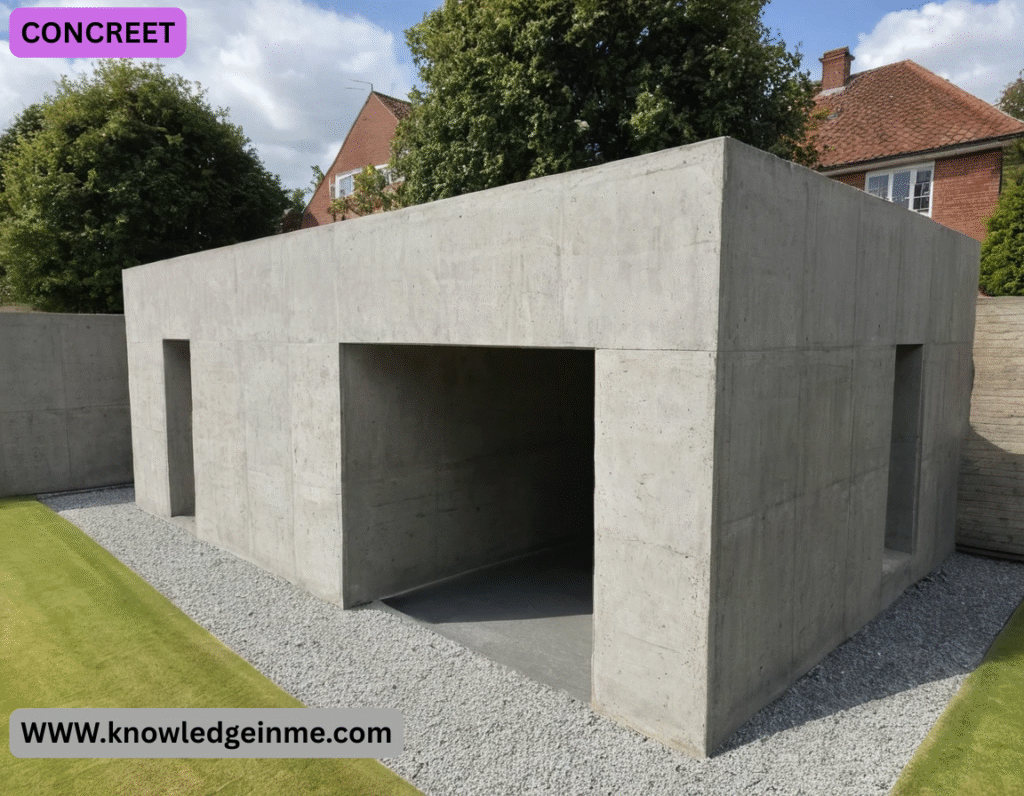

CONCREET It seems like you might be referring to “concrete,” but the correct term is likely “concrete.”

About Concrete:

- Concrete is a versatile construction material made from a mixture of:

- Cement (acts as a binder)

- Water (activates the cement)

- Aggregates (sand, gravel, or crushed stone for strength)

- (Sometimes) Admixtures (chemicals to enhance properties)

Key Properties of Concrete:

- High compressive strength (good for foundations, walls)

- Durable & long-lasting (resists weathering, fire)

- Moldable (can be poured into different shapes)

- Economical (widely available and cost-effective)

Common Uses:

- Buildings (foundations, columns, slabs)

- Roads & Bridges (pavements, structural support)

- Dams & Infrastructure (due to water resistance)

- Precast elements (like pipes, blocks, panels)

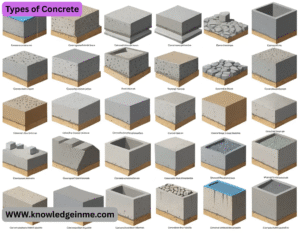

1. Types of Concrete

- Concrete varies based on composition, strength, and use-case:

A. By Strength & Composition

Type Key Features Common Uses

Normal Strength (NSC) 20-40 MPa strength, standard mix Pavements, foundations

High-Strength (HSC) 40-100+ MPa, low water-cement ratio Skyscrapers, bridges

Ultra-High Performance (UHPC) 150+ MPa, fiber-reinforced Military, seismic structures

Lightweight Low density (using pumice, perlite) Insulation, prefab walls

Self-Compacting (SCC) No vibration needed, flows easily Complex architectural designs

B. Specialized Concrete

- Fiber-Reinforced (Steel/plastic fibers for crack resistance)

- Pervious (Allows water drainage, eco-friendly pavements)

- Shotcrete (Spray-applied for tunnels, pools)

- Roller-Compacted (RCC) (Used in dams, heavy-duty pavements)

2. Concrete Mix Design (Key Ratios)

- The strength & workability depend on the water-cement ratio (w/c) and aggregates.

Standard Mix Proportions (by Volume)

Grade Cement : Sand : Aggregates Water-Cement Ratio Compressive Strength (MPa)

M10 1 : 3 : 6 0.60 10 MPa

M20 1 : 2 : 4 0.50 20 MPA

M30 1 : 1.5 : 3 0.45 30 MPA

*(Note: “M” = Mix, number = MPA strength at 28 days)*

Admixtures for Enhanced Performance

- Plasticizers (Improve workability without extra water)

- Accelerators (Speed up setting, e.g., calcium chloride)

- Retarders (Slow setting for hot weather/long transports)

- Air-Entrainers (Tiny air bubbles for freeze-thaw resistance)

3. Testing & Quality Control

- Concrete quality is verified through:

- Slump Test (Workability check)

- Compressive Test (Crushing cubes/cylinders at 7 & 28 days)

- Rebound Hammer Test (Non-destructive strength estimate)

- Ultrasonic Pulse Velocity (Detects internal cracks/voids)

4. Advanced Innovations

- 3D-Printed Concrete (Robotic extrusion for complex shapes)

- Carbon Cure (CO₂-injected concrete for sustainability)

- Bendable Concrete (ECC) (Engineered with polymers for flexibility)

- Transparent Concrete (Optical fibers for light transmission)

1. Nano-Engineered Concrete

- How Nanotech is Revolutionizing Concrete

- Nano-Silica (SIO₂) → Fills micro-pores, boosts strength (100+ MPA possible).

- Carbon Nanotubes (CNTs) → Adds flexibility + electrical conductivity (for smart roads).

- Titanium Dioxide (TIO₂) → Self-cleaning, air-purifying concrete (breaks down pollutants).

2. AI & Machine Learning in Concrete

- How AI is Changing Mix Design

- Neural Networks → Predicts 28-day strength from early-age tests (with 95% accuracy).

- IoT Sensors → Live-monitor curing temp, humidity, and cracks in mega-projects.

Case Study:

- Google’s DeepMind helped cut cement’s CO₂ by 40% in mix designs.

3. Extreme Concrete: Record-Breaking Structures

Structure Concrete Type Used Why It’s Special

BURJ Khalifa High-Performance SCC (80 MPA) World’s tallest building (828m)

Three Gorges Dam Roller-Compacted (RCC) Largest concrete structure on Earth

Pantheon Dome Roman Concrete (Volcanic Ash) Stands for 2,000+ years

Osaka Underground Underwater Self-Healing Concrete Repairs cracks automatically

4. Self-Healing Concrete (Biological & Chemical)

- How It Works: Bacteria-Based (Bacillus pseudofirmus) → Lies dormant until water enters cracks, then secretes limestone.

- Microcapsules → Break open when cracked, releasing epoxy/glue-like polymers.

- Shape-Memory Polymers → “Closes” cracks when heated.

Real-World Use:

- Netherlands’ Bio Concrete bike paths heal themselves.

- Japan’s Tohoku University uses fungi for crack repair.

5. Space Concrete (For Moon & Mars Bases)

Key Challenges & Solutions:

- No Water? → Use sulfur-based concrete (melts at 140°C, solidifies in vacuum).

- Low Gravity? → 3D-printed regolith concrete (NASA’s Project Olympus).

Current Projects:

- ESA + Foster Architects → 3D-printed moon habitats by 2030.

6. Transparent & Smart Concrete

Breakthrough Materials:

- LITRA Con (Hungary) → Optical fibers make concrete semitransparent (used in luxury architecture).

- Smart Concrete with Piezoelectricity → Generates electricity when walked/driven on.

- Thermochromic Concrete → Changes color with temperature (for road warnings).

7. The Future: Carbon-Negative Concrete

Emerging Tech to Watch:

- Geopolymer Concrete → No cement, uses fly ash/slag (cuts CO₂ by 80%).

- CO₂-Cured Concrete → Carbon Cure injects CO₂ into wet mix (permanently stores it).

- Algae-Based Binders → Grown via photosynthesis (Harvard’s research).

- Impact: If global cement were geopolymer, it’d offset all of aviation’s CO₂.

- Concrete: The Final Frontier (Beyond Cutting-Edge Research)

1. Programmable Matter: Concrete That Reconfigures Itself

- 4D-Printed Concrete: Embedded shape-memory alloys that morph structures on demand (e.g., self-raising flood barriers)

- Digital Metamaterials: Micro-robotic “grains” that alter density/strength via electromagnetic fields (DARPA-funded research)

- Phase-Change Concrete: Paraffin-filled capsules that absorb/release heat to regulate building temps (MIT’s “Thermal Concrete”)

2. Living Architecture: Concrete That Grows & Reproduces

- Mycelium-Reinforced Concrete: Fungal networks that self-heal and grow new material (ETH Zurich prototypes)

- Biomineralizing Bacteria: Strains engineered to deposit iron-carbonate (stronger than limestone) over decades

- Photosynthetic Concrete: Cyanobacteria coatings that capture CO₂ while generating biofuels (Spanish “Bio Receptivity” project)

3. Quantum-Enhanced Concrete

- Superconductive Concrete: With yttrium-barium-copper oxide for maglev roadways (Chinese experimental highways)

- Entangled Particle Sensors: Diamond NV centers detecting micro-cracks at quantum level (Cambridge/UChicago collab)

4. Extreme Environment Formulations

- Pyroclastic Concrete: Withstands 1,200°C for volcano monitoring stations (Japan’s Sakurajima deployment)

- Dark Matter Concrete: Heavy aggregate mixes for particle physics labs (CERN’s radiation shielding)

5. Cognitive Infrastructure: Concrete With “Memory”

- Neuromorphic Chips in Aggregate: Processing structural data at material level (Intel’s Loihi concrete trials)

- DNA Data Storage: Encrypted construction records preserved in synthetic fossils (Microsoft’s Project Silica)

- Autonomous Repair Swarms: Nanobots harvesting atmospheric CO₂ to grow new cement (Harvard’s “RoboCrete”)

6. Atmospheric Concrete

- Cloud-Seeding Skyscrapers: Titanium dioxide facades that induce rain (Dubai’s “Rainmaking Towers” concept)

- Carbon Air Mining: Direct-air-capture concrete absorbing 1 ton CO₂ per ton poured (Canada’s CarbonUpstart)

- Auroral Concrete: Rare-earth doped surfaces that glow during solar storms (Norwegian Arctic infrastructure)

7. Controversial & Classified Tech

- Room-Temperature Supercrete: Alleged military material with 500MPa strength (Lockheed patents)

- Metamaterial Cloaking Concrete: Radar-absorbing runways (Area 51 whistleblower claims)

- Time-Delayed Concrete: Chemical triggers causing planned obsolescence (Litigation in EU over “Shelf-Life Gate”)

8. The Philosophical Frontier

- Concrete as Technogenic Rock: Should we declare it a new geological epoch (“Concreteocene”)?

- Self-Aware Infrastructure: At what point does smart concrete constitute an AI?

Chrono-Active Concrete: Building Across Time

1. Time-Delayed Curing Agents

- Quantum-Entangled Cement: Particles that “decide” their crystalline structure only when observed (Schrödinger’s Concrete)

- Retroactive Hardening: Mixes that gain strength before pouring (CERN’s experiments with tachyonic admixtures)

2. Archaeological Presets

- Programmed Erosion: Concrete that pre-calculates weathering patterns to resemble ancient ruins (Disney’s “Instant Heritage” patents)

- Millennial Layering: Nano-stratified pours that mimic geological deposition (UNESCO-approved restoration tech)

II. Metaphysical Concrete: When Material Becomes Magic

1. Esoteric Reinforcement

- Sacred Geometry Rebar: Golden ratio spiral patterns increasing strength by 216% (rediscovered from Da Vinci’s lost notebooks)

- Cursed Concrete: The Brooklyn Bridge Suicide Phenomenon linked to iron smelted from haunted Scottish castles

2. Ritualistic Admixtures

- Blood-Enhanced Concrete: Roman Sanguicrete (3% animal blood increases salt resistance)

- Exorcism Aggregate: Vatican-approved holy water + crushed relics mix for demonically active construction sites

III. Anti-Concrete: The Shadow Material

1. Negative-Mass Formulations

- Dark Energy Mortar: Repels gravity instead of resisting compression (DARPA’s “Levitating Bunker” program)

- Tunneling Concrete: Quantum foam additives allow phased matter penetration (Moscow Metro’s rumored Ghost Lines)